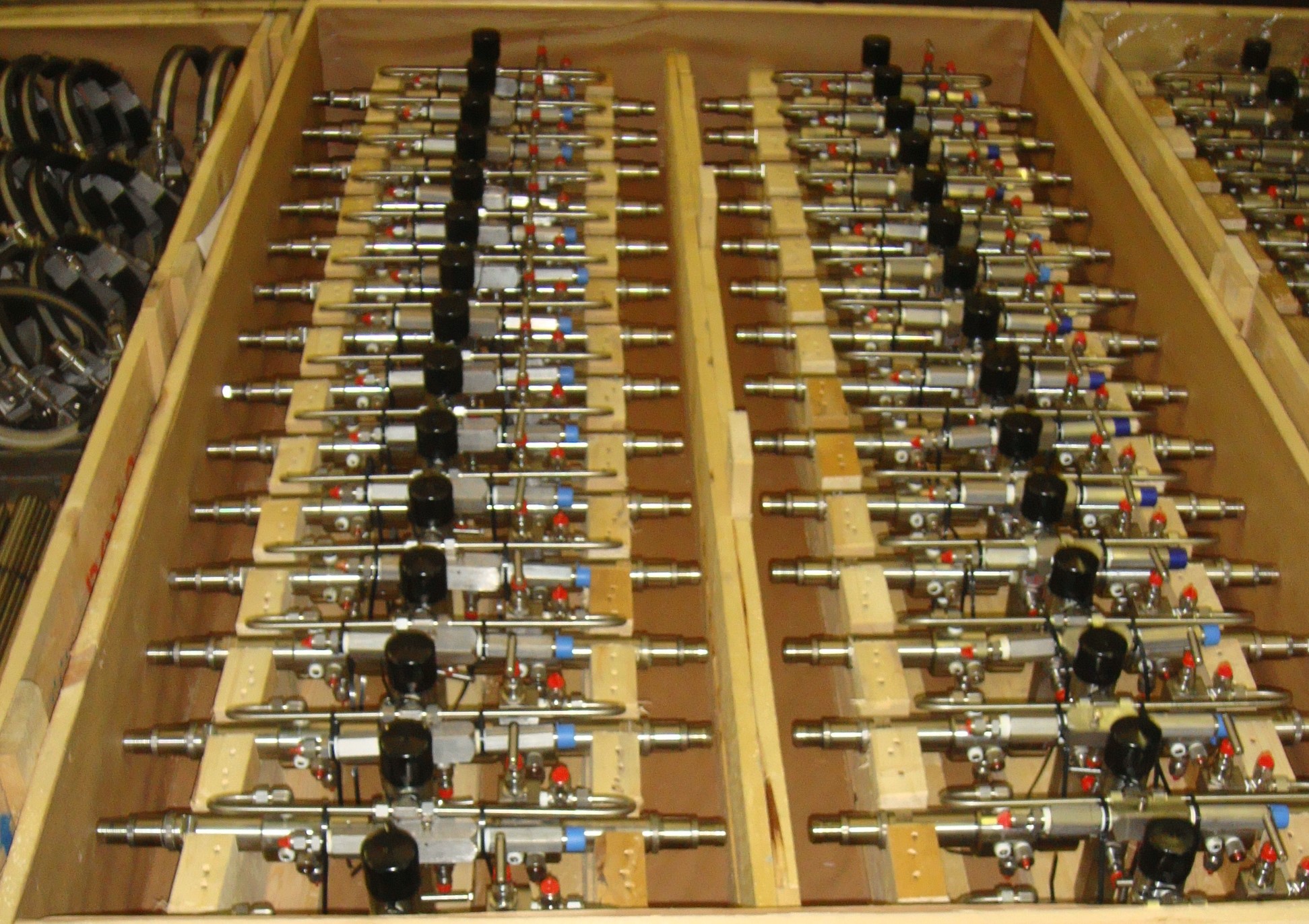

The Line Pressure Operated (LPO) system takes fluid / gas from the flowline or X-mass tree or valve flange tapping point through instrument valves and pilots into the actuator and controls all of the actions of the actuated valve according to the conditions set for the process downstream of the safety system.

The system has been designed to operate one high-pressure actuator mounted on a reverse acting gate valve with the control pressure coming from the flowline/pipeline. The maximum operating pressure will be 6.000 PSI gas of crude oil mixed with associated gas. The system has a high-pressure pilot installed to offer protection to the pipeline or downstream installation(s). The low-pressure pilot will give protection for a low-pressure condition, which could indicate a broken pipeline downstream of the system. Tattle tales are installed to indicate which pilot – high or low, has been tripped. The system requires no electrical power or external power source other than flowline/pipeline pressure.